Location

Digital Making DJCAD

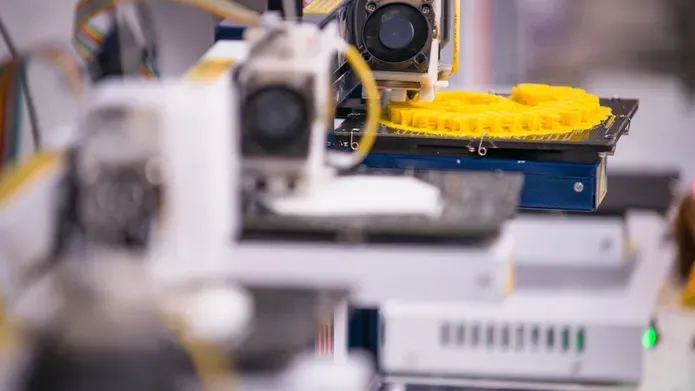

We provide a range of digital making equipment, including 3D printers, laser cutters, CNC milling as well as digital electronics

Room 407

Level 4

Crawford Building

DD1 4HY

Accessibility

View accessibility information for the Crawford Building (DJCAD) on AccessAble

About

We instruct students in the use of many types of digital fabrication equipment and attendant software and techniques. Our main practices include 3D printing, laser cutting and engraving, CNC milling, vinyl cutting, digital electronics and programming, 3D scanning and photogrammetry.

3D Printing

We have a wide range of 3D printers available for use with a variety of materials and to different scales:

- 6 x UP! Box/Box+ printers (max. build volume 255×205×205mm)

- 6 x UP! Mini2 printers (max. build volume 120×120×120mm)

- 7 x UP! Plus2 printers (max. build volume 140×140×135mm)

- 2 x Ultimaker 2+ printers (max. build volume 223×223×205mm)

- 3 x Ultimaker 2+ Extended printers (max. build volume 223×223×305mm)

- 2 x Ultimaker 3 Extended dualextruder printers (max. build volume 197×215×300mm)

- 1 x LulzBot Taz 6 w/dual flex extruder (max. build volume 280×280×250mm)

- 1 x Formlabs Form1 resin printer (max. build volume 125x125x165mm)

We mainly use ABS and PLA thermoplastics, as well as specialist materials including filaments impregnated with copper, bronze, wood and carbon fibre, and flexible and electrically-conductive plastics.

Laser Cutting

We have six laser cutters ranging in size from 600 x 300mm to 1500 x 1000mm, which students can use to work in a variety of sheet materials such as woods, plys, MDF, papers, fabrics, stone and concretes, glass and acrylics. We can also laser cylindrical objects such as bottles, bowls and other vessels. We mainly use Adobe Illustrator and Autodesk Autocad to send files to the laser cutters.

All students are given a comprehensive induction in laser cutting and etching.

Use of the lasers is controlled by an online booking system.

CNC Milling

We have 2 CNC milling machines, allowing us to mill a variety of materials such as wood, foams, plastics and non-ferrous metals:

- Roland MDX-40a CNC mill (max. milling volume 305x305x105mm)

- Denford 6600 Pro CNC router/mill (table size 1080x640mm)

Vinyl cutting

We have a large-format (1200mm-wide) Summa D120 vinyl cutter which is perfect for making adhesive signage, but can also be used as a plotter.

3D modelling and photogrammetry

We have access to most popular 3D modelling/design software titles, such as Rhinoceros 3D, Autocad, Fusion 360, Solidworks and Sculptris for creation of 3D parts which can then be presented to our 3D printers or CNC mills. We also use Agisoft Photoscan to render 3D models from photogrammetry image sets.

Electronics

We have six electronics workstations equipped with soldering stations, bench power supplies, measurement meters and extraction, so that students can build working electronic circuits. We also have expertise in the use of microcontrollers such as Arduino, Electric Imp and Raspberry Pi, and assist students in embedding working technology into their designs, products, artworks and installations - we do anything from simply adding illumination to making objects communicate over the internet.